Solutions For Solving Issues With Buchholz Relay

Publish Date: 2021-08-02

Here at Energypac Engineering, we believe in learning as a continuous process irrespective of age or non-engineering educational background. Whilst a substation employs sophisticated technology and requires extensive knowledge of the technical aspects of the power equipment, it is always handy to know some key characteristics which will enable any novice to understand important operational features of the substation equipment.

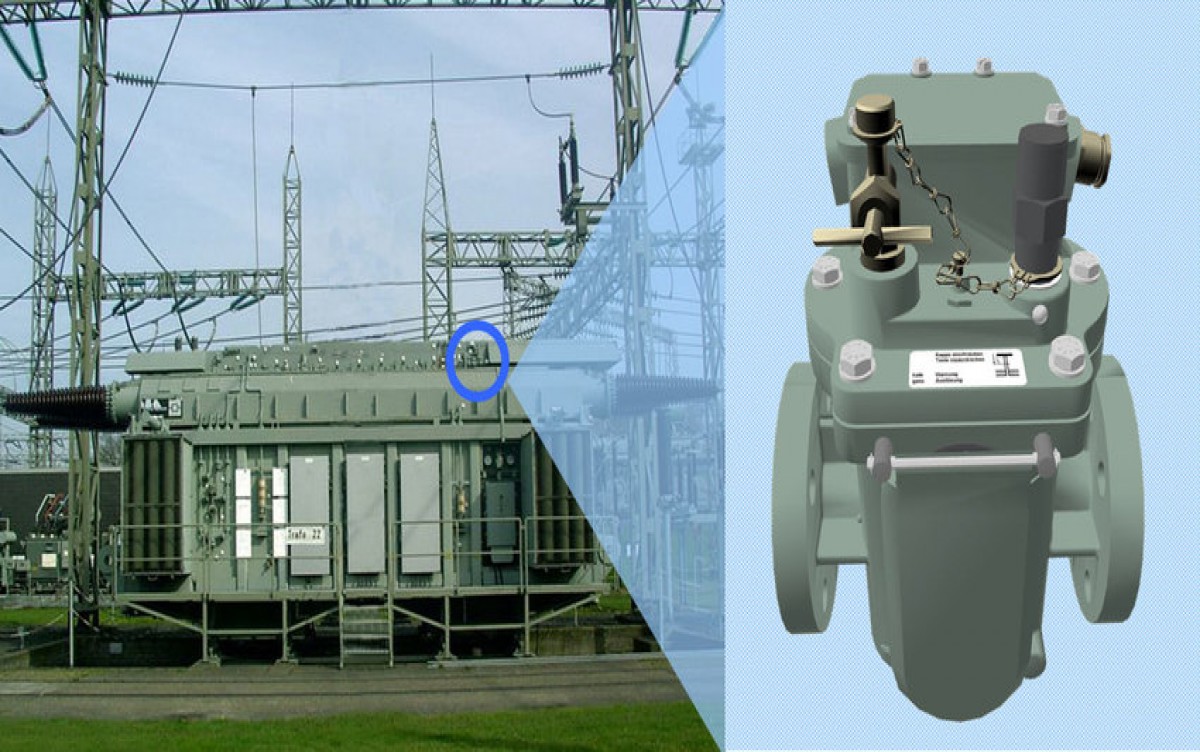

One such piece of equipment is the Buchholz relay that comes with the transformer. The Buchholz relay serves as a protection device for the transformer and prevents short circuits, gas collection, oil surge, or any other faults. If a fault were to ever arise then the relay will simply shut the alarm circuit indicating to any observer that there are complications that need to be resolved before restarting the operation.

The relay does this through two processes: Gas Collection and Oil Surge.

Gas Collection: The relay collects any gas element escaping from the transformer and shuts contact as soon as the gas reaches a certain limit. If more gas were to be produced after this limit then the trip falls discontinuing the operation. This can happen as a result of oil surge from partial discharge within the transformer, low oil level, overheating of the windings, air entering the transformer from outside, or shock and vibration.

Oil Surge: The Buchholz relay is pre-set to operate and close contact at a certain oil velocity. This occurs due to oil surges from the main tank towards the conservator, electrical breakdown, disruption in pump operation, or if the Buchholz was mounted incorrectly.

Without delving too deep into the inner workings of the relay, it is crucial to note that sometimes these precautionary tripping can take place without a genuine cause or danger. In such a case, this false trip requires troubleshooting to restart the operation without losing valuable time.

Some necessary preventive actions that can be taken after the Buchholz alarm is set off, are given below

- Take oil samples from the main tank as well as any other oil-filled compartments with high voltage parts to send to the laboratory for immediate testing of dissolved gas analysis.

- Check for the presence of gas in the relay and record the volume of the gas found and send this gas to the laboratory for analysis.

- Check all the pressure relief devices for any ruptures in the diaphragm in the explosion vent.

- Check for leakage of oil around pressure relief devices as well as for tank joints.

- Check whether there was any distortion of the tank including the tap changers.

- It is also important to check the level of oil in bushings and tap changer diverters.

- While you are at it, might as well check electrical protection and fault recorders for operation.

Whilst the steps provided above are not exhaustive, it is a good place to start to gather enough information to decide on the next operational action.